Turbidity measurement for filter backwashing

In water treatment, a variety of filters (sand, gravel, membrane) are used to remove suspended solids and sometimes also microbiological substances. After a certain time, all filter materials are saturated and need to be rinsed. For this purpose, the treated water is pumped through the filter medium under pressure in the opposite direction. With the AquaScat 2 WTM A or the AquaScat 2 HT, a filter backwash can be efficiently controlled by indicating the optimum time for a backwash based on the turbidity measurement.

As a rule, filters must be flushed every 48 hours. The water that has already been treated is often backwashed with compressed air or pressurized water and discarded. During this backwash, the filter is freed from suspended particles and can then be reused. Due to the preceding sedimentation stage, large suspended solids have already been removed from the water.

After filter backwashing, the first filtrate is usually discarded, as high levels of solids may still be present at the beginning.

The Solution

The AquaScat 2 WTM A or AquaScat 2 HT efficiently controls filter backwashing. There are two ways to do this:

Simple version

The turbidity is measured after the filter. If it increases steadily, this is an indication that the filter is slowly becoming saturated. A limit value is set for the turbidity. If this value is exceeded, an optical or acoustic signal can be triggered at the filter using one of the digital outputs, for example. This indicates to the operator that backwashing is necessary.

Advanced Version

In addition to the turbidity, the flow rate at the filter is also measured. The latter is an indication of the amount of water flowing through the filter. This shows the saturation of the filter even more clearly. With the AquaScat 2 WTM A, for example, the input for flow meters can be used for this purpose. With the help of mathematical channels, empirical values for each filter station can be easily stored for each customer. When limit values are reached, alarms can then be issued directly at the filter location or alternatively on the control system.

Schematic of a core filtration system in a water supply system

Customer Benefit

- The customer saves water and the associated water costs.

- The customer saves energy (operation of pumps for backwashing).

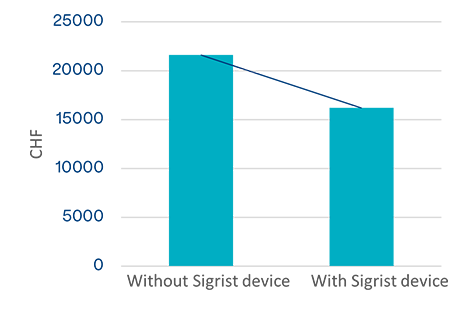

Without Sigrist device

- Filter backwashing requires 150 m3 of water and is necessary every 48 h

- Average price for drinking water 1.5 CHF/m3, for cleaning 0.8 CHF/m3

- 180 flushing cycles in one year → 27‘000 m3 water are needed for backwashing

- Costs = 21‘600 CHF excl. prices for energy!

With Sigrist device

- The backwash cycle is only performed as required.

- Optimization: 25 % (tends to be more)

- Costs = 16‘200 CHF

Further Advantages

- True non-contact measurement in free-fall stream

- Re-calibration with secondary standard (fully automatic)

- Lowest stray light levels

Practical Measurement Task (Example)

A similar concept also applies to activated carbon filters for the removal of dissolved organic substances. Here, the SAK254 content in the water is measured after filtration. Instead of filter backwashing, the substances in the activated carbon are removed by heating, for example. With a suitable process control system, this filter cleaning can be carried out as required, thus reducing operating costs.

Contact distribution partner

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters