Turbidity Measurement for Phase Separation

Phase Separators are devices used in industrial processes to separate different phases of a mixture, typically liquid-liquid or gas-liquid systems. They are essential in applications ranging from oil and gas production to chemical processing and wastewater treatment. For this reason, measurements like conductivity or turbidity are often used to monitor and control the separators performance.

Operators want to distinguish the liquid components (e.g. washing solution from sample). For this reason, measurements like conductivity or turbidity are often used to monitor and control the separators performance at the separator exit to the process or to the waste stream (or at both sides). Let’s take the washing cycles as an example. After the process is finished the operators will use either CIP (Cleaning in Process) or SIP (Sterilization in Process) to clean the sample lines before a new product batch is started.

Still in the 21st century, certain chemical plants use manpower to observe phase separations. This is highly risky and can cost thousands of francs because some phase changes are difficult to catch by eye.

The Solution

The TurBiScat 2 Ex is a reliable in-line process turbidimeter. It can be used for several tasks in a separator such as:

- Interface detection between the different phases

- Process control for real-time feedback of the separation process and adjustment of parameters such as flow rate accordingly

- Quality assurance to provide information in the contamination level of a specific product

With the TurBiScat 2 Ex the phase separation process can be monitored efficiently. In contrast to conductivity probes the reaction time of our turbidimeter is by a factor of 10x faster at least! Therefore, the separated phases are detected, and the product waste can be reduced to a minimum. Our turbidimeter can either use the 25° or the 90° angle to distinguish the liquids using light scattering. In addition, a color compensation can be applied if necessary. Depending on the configuration of the plant all signals are transmitted either as analogue or digital. Limits are easily set on the instrument directly or in the PLC system.

The Customer Benefit

- More efficient automation of process results in higher revenue

- Cross sensitivities are less of a problem because color can be compensated results in reliable process monitoring.

Extract from Technical Details

Wavelength turbidity: LED 650 nm

Wavelength color (optional): LED 430 nm

Measuring principle: 90° / 25° scattered light at 650 nm (optional color measurement at 430 nm)

Ex-protection type: Ex db IIC T3/T4/T5/T6 Ga/Gb

Operation: Proximity sensor

Typical Application

A separator is for example used at the beginning of crude oil distillation. Sediments and water in the incoming crude are removed, leaving organic product for the distillation column. The water goes either into a special tank or directly into the wastewater treatment process.

Further Practical Measuring Tasks

The TurBiScat 2 Ex is also used to monitor turbidity during Whiskey or Cognac production. Typical measurement points can be found after filtration before the spirit is stored in wooden tanks.

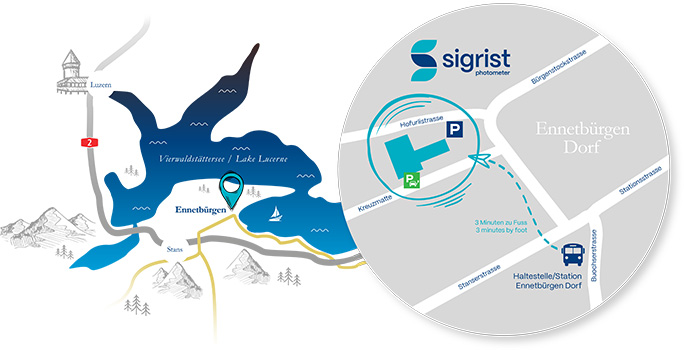

Contact distribution partner

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters