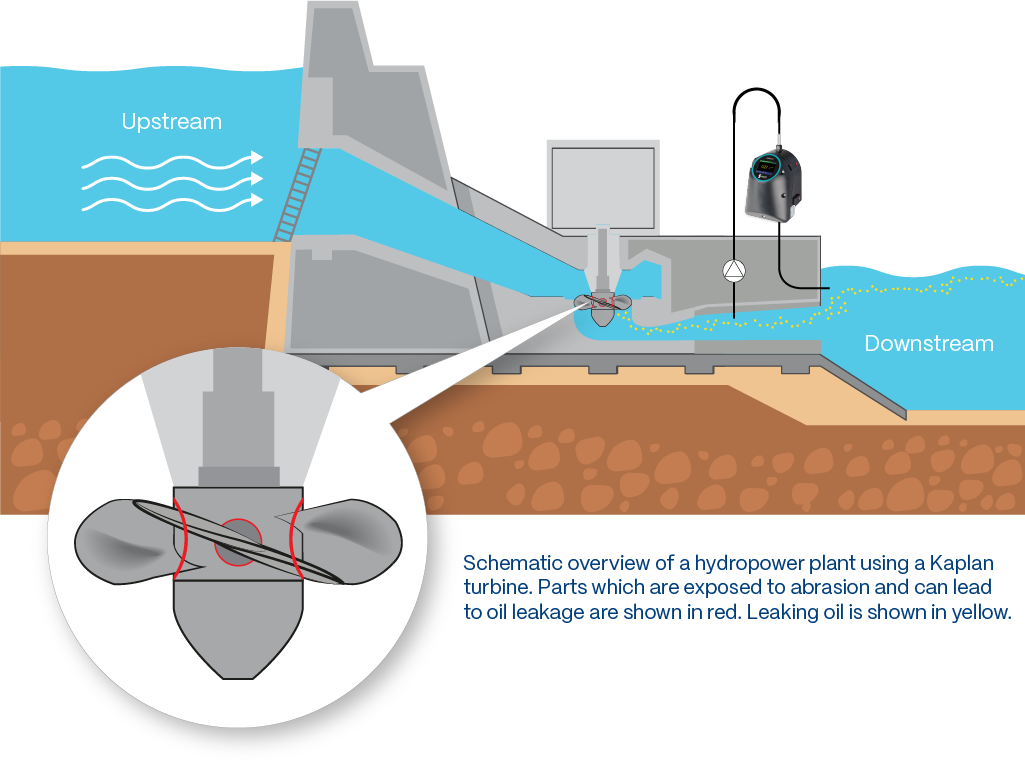

Detecting oil leaks from turbines

Where electrical energy is produced by a hydropower plant, rotating parts are exposed to water. These

rotating parts are lubricated by grease or lubricating oil. Wear and abrasive particles in the turbined water

such as sand attack the bearings. This circumstance is a potential source of oil leaks, which poses a risk

to the aquatic environment or drinking water supplies downstream of the turbine.

The challenge

In case of an oil leak at a large hydropower plant, several litres of lubricating oil may be released into the environment. Beside threats to the environment, broken bearings reduce efficiency during operation and therefore reduce the produced energy.

Depending on the turbine, different components areaffected by oil leaks:

- Kaplan turbine: hydrodynamic bearing, adjustable runner blades

- Pelton turbine: jet deflector, nozzle needle, shut-off device

- Francis turbine: hydrodynamic bearing,

adjustable guide vanes, hydraulic servos

The solution

With the OilGuard 2 W Sigrist offers an instrument

for continuous monitoring of water in hydropower

applications. It can be used to detect oil traces from

petroleum-based lubricants. This allows hydropower

plant operators to monitor turbines during operation

without a need to carry out laboratory tests or a

shutdown of the plant.

The continuous measurment of oil traces allows the

hydropower plant operator to quickly identify an

oil leak. The operator is able to initiate immediate

measures and prevent further damage to the turbine.

Such rapid and appropriate measures also minimise

the amount of contaminated water released into

the environment and can prevent difficulties with

the water protection authorities or possible claims

for compensation from the public. In most cases

of a shutdown, the loss of energy produced and damage

to the environment exceeds the cost of

the measuring device.

The continuous monitoring of oil traces also provides

operators valuable information about the condition

of the turbines in operation. For instance, it allows to

plan upcoming maintenance work or better estimate

the addition of lubricant.

Technical details

The Sigrist OilGuard 2 W A is a continuously operating instrument that reacts reliably and quickly to the smallest traces of oil. The instrument measures the fluorescence* properties of hydrocarbons in petroleum- based lubricants, fuels and oils when they are mixed with the water. Due to this measuring principle, the measurement is not negatively affected by turbidity. Thanks to the non-contact free-fall measurement, the OilGuard 2 W does not suffer any falsification of measured values as a result of window contamination. In addition, the integrated automatic calibration function checks and recalibrates the device fully automatically during measurement operation. If the device detects a measurement error, it automatically issues an error message. This offers the user maximum safety and maximum device availability.

*Other sources of fluorescence in the water have an

influence on the measurement and require additional

evaluation.

Further applications

- Detect oil leaks in the drainage water of power station central and reservoirs

- Detect traces of oil in the drainage water of waste disposal sites

- Detect oil leaks in snowmaking systems

- Detect traces of oil in drinking water reservoirs

Contact distribution partner

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

For water, industrial processes, traffic & environment please contact our headquarters