Brau Beviale 2011: SIGRIST-PHOTOMETER AG, hall 6 / stand 6-411

The TurbiGuard is used for monitoring medium to high turbidity, in process liquids. A single version of the TurbiGuard featuring two measuring ranges can be widely used for monitoring medium to high turbidity.

The TurbiGuard is factory calibrated with a

The PhaseGuard monitors phase transitions of turbidity or colour. Three models of the PhaseGuard cover the possible applications: phase switch for turbidity (model T), for colour (model C), for high turbidity (model HT). The PhaseGuard is factory adjusted

The PhaseGuard monitors phase transitions of turbidity or colour. Three models of the PhaseGuard cover the possible applications: phase switch for turbidity (model T), for colour (model C), for high turbidity (model HT). The PhaseGuard is factory adjusted

The PhaseGuard monitors phase transitions of turbidity or colour. Three models of the PhaseGuard cover the possible applications: phase switch for turbidity (model T), for colour (model C), for high turbidity (model HT). The PhaseGuard is factory adjusted

The TurBiScat monitors turbidity in liquids, optional also the (beer)colour in EBC. The combination of Hastelloy and sapphire in a sealless design allows operating the unit in practically all process applications. Turbidity measurement is done with colour

Contact distribution partner

Leonardo Pio

Responsible for the application: Water, Industrial Processes, Beverages & Food for the regions: AG, LU, NW, OW, VS, BS, BL, SO, BE, FR, NE, VD, GE and JU

Phone: +41 79 413 54 24

Andreas Corradini

Responsible for the application: Water, Industrial Processes, Beverages & Food for the regions: TI, GR, UR, GL, SZ, ZG, ZH, SH, SG, TG, AR and AI Traffic & Environment: whole Switzerland

Phone: +41 79 641 25 64

Ihr Businesspartner für Getränke & Lebensmittel:

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

Your distribution partner for beverages & food:

For water, industrial processes, traffic & environment please contact our headquarters

For water, industrial processes, traffic & environment please contact our headquarters

Ihr Businesspartner für Getränke & Lebensmittel:

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

Für Wasser, Industrielle Prozesse, Verkehr & Umwelt kontaktieren Sie unseren Hauptsitz.

Your distribution partner for beverages & food:

For water, industrial processes, traffic & environment please contact our headquarters

For water, industrial processes, traffic & environment please contact our headquarters

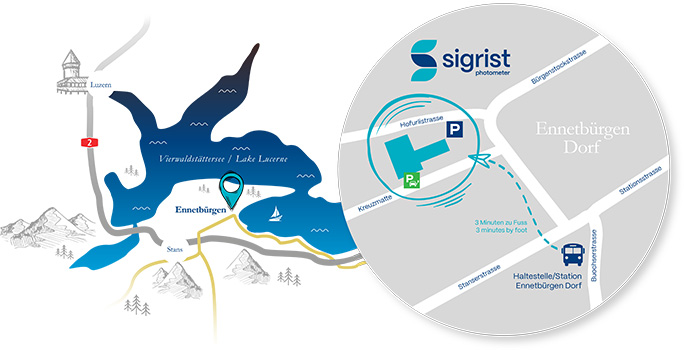

Contact headquarters

Öffnungszeiten:

Montag–Freitag 08:00–12:00 und 13:30–17:00

Feiertage & Betriebsferien:

Seppitag: 19. März 2025, Ostern: 18. – 21. April 2025, Auffahrt: 29. Mai 2025, Pfingstmontag: 9. Juni 2025, Fronleichnam: 19. Juni 2025, Bundesfeiertag: 01. August 2025, Maria Himmelfahrt: 15. August 2025, Allerheiligen: 01. November 2025, Maria Empfängnis: 08. Dezember 2025, Betriebsferien: 24. Dezember 2025 – 04. Januar 2026

Opening hours:

Monday–Friday 08:00am–12:00pm und 1:30pm–5:00pm

Public & company holidays:

St Joseph's Day: 19. March 2025, Easter: 18. – 21. April 2025, Ascension Day: 29. May 2025, Whit Monday: 09. June 2025, Corpus Christi: 19. June 2025, Federal Holiday: 01. August 2025, Assumption Day: 15. August 2025, All Saints Day: 01. November 2025, Conception of Mary: 08. December 2025, Company holidays: 24. December 2025 – 04. January 2026