A. Rogner

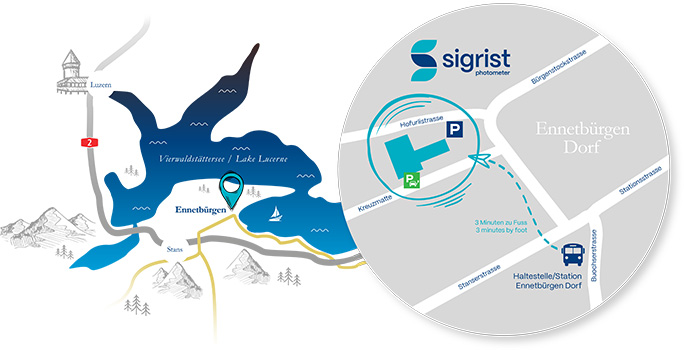

SIGRIST-PHOTOMETER AG, Hofurlistrasse 1, CH-6373 Ennetbürgen, Switzerland

Abstract

A new generation of continuous particulate matter concentration

monitoring instruments is presented, covering a measuring range of 0 to

1000 mg/m3. The laser-based scattered light instrument gives an

improved stability as well as excellent resolution in the low range. This

enables high concentration measurement as well as especially low emission

monitoring down to 0.01 mg/m3 with a resolution of 0.001 mg/m3.

The high stability of the laser light source, a purge air system avoiding

pollution of the optical interfaces and an automatic drift check system

allow a maintenance interval of three months. The monitoring is done in an

extractive sampling line heating the gas up to 160°C thus allowing the

monitoring of wet gases.

1 Introduction

Forced by governmental regulations with decreasing emission limits as the

new European directives 2000/76/EG for waste incinerators and 2001/80/EG for

power plants, the technology for reducing particulate matter emission has

been continuously improved over the last years. Latest state-of-the-art

waste incinerators and combustion facilities in standard operation emit

particle concentrations of 0.1 mg/m3 or even less (TÜV-Bericht:

936/806015, 1997).

To ensure a reliable control of these low emissions and the related

cleaning process, particulate matter measuring instruments also had to be

improved. These instruments should have at least a resolution of 10% of the

lowest emission values given above, i.e. 0.01 mg/m3, to make

changes detectable and to demonstrate the instruments functionability. On

the other hand, peak emission values in countries with more moderate limits

or for older facilities can reach up to 200 mg/m3. So a

multi-purpose instrument suited for installations in a variety of industries

and applications like waste incinerators, power plants, refineries, cement

kilns, etc. has to cover a broad measuring span with a high dynamic

resolution.

In addition, the new European Standard EN 14181 for quality assurance of

automated measuring systems and the new suitability requirements for

continuous emission monitoring systems in EN ISO 14956 brought further

requirements for new measuring equipment as automatic drift and reference

point check including logging functions.

2 Principle of detection

2.1 Scattered light measurement

The newly developed StackGuard instrument is based on its predecessors

CTNR and KTNR, which have been installed in about 350 facilities since more

than 20 years and successfully used in a variety of applications and

industries. Similar to these instruments, the StackGuard is using the

scattered light detection for particulate matter concentration measurement

(Fig. 1). A light beam with certain intensity is striking the sample. Due to

absorption and scattering at the dust particles, the transmitted light

intensity is reduced. This effect is used in the measurement principle of

opacimeters especially for high particle concentrations. To detect high and

also low particle concentrations, the detection of the scattered light is

necessary. In the StackGuard, a certain part of the scattered light is

detected under a 20° angle.

|

| Figure 1: Scattered light measurement |

The intensity of the scattered light shows in this concentration range a

linear relation to the concentration of the particles, as long as the

particle properties like size, shape, color, or refractive index do not

change. As demonstrated in paragraph 4, a calibration of the instrument can

be done using a linear fit between the scattered light intensity and the

particulate matter concentration determined by a reference method. Using

this calibration, the read-out of the instrument can be displayed in mg/m3.

For different particle properties, the scattered light intensity and

distribution might also be different (Huber and Frost, 1998). For most

applications in dust emission measurement these variations are negligible in

the concentration range of interest and the linear fit is still appropriate.

In some applications, however, especially with a wide span of the

concentration or a variety of different fuels, the particle properties like

e.g. the size distribution are changing with changing concentration. In

these cases the best fit method for the calibration curve might be different

from linear, e.g. quadratic or logarithmic. Due to this fact, for all light

scattering CEMS, a calibration has to be done on-site after installation of

the instrument.

2.2 Optical setup

The completely revised setup of the StackGuard instrument is given in

Figure 2. The measurement is done in two phases:

Phase 1: The laser remains switched off. The zero points of the three

detectors are determined. This is especially important to reduce any

zero-point offset and thus improve the accuracy at low dust levels. The

laser is a temperature controlled semiconductor laser light source with a

wavelength of 650 nm.

Phase 2: The temperature-stabilized laser is switched on. The light

impinging on the two reference detectors and the 20° scattered light

detector is measured. The measurement reading is calculated from these

signals.

Using this two-beam method, a continuous determination and compensation

of all uncertainties and errors due to intensity changes and fluctuations of

the light source and ageing effects of the electronics is achieved. Any

additional drifting is well-proven to be below 2% per 3 months and can be

easily compensated by re-calibrating the instrument by inserting glass-rods

with a given opacity.

Moreover, the improved sensitivity of the light detecting circuits gives

a dynamic range of more than 105 for the scattered light intensity thus

covering a concentration range from 0.0005 mg/m3 PLA to 100 mg/m3

PLA. The appropriate measuring range is selected by automatic range

switching.

The signal ratio of reference detector inlet (3) to reference detector

outlet (7) gives an information on the pollution of the optical components

and is monitored continuously. When a certain limit is exceeded, a warning

is generated.

|

| 1 |

Temperature-stable laser |

| 2 |

Partially permeable mirror |

| 3 |

Reference detector inlet |

| 4 |

Tilted mirror |

| 5 |

Flow cell |

| 6 |

Purge air shroud |

| 7 |

Reference detector outlet |

| 8 |

Scattered light detector |

| 9 |

Automatic checking unit, consisting of: |

| 10 |

Partially permeable mirror |

| 11 |

Attenuator |

| 12 |

Shutter |

| 13 |

Scattered light body |

| 14 |

Actuator for attenuator and shutter |

|

| Figure 2: Optical setup of the StackGuard |

An additional improvement in the StackGuard is an automatic zero and

reference point drift check system (see also Figure 2). Every 24 hours, the

system undergoes the following check procedure:

1. Measuring position: Part of the laser light is decoupled with a

partially permeable mirror (10). When the checking unit is in the measuring

position, the attenuator (11) blocks this checking beam. The shutter (12) is

open and lets the scattered light from the flow cell pass through. It is

detected by the scattered light detector (8).

2. Reference point check value: The attenuator (11) lets pass the

checking beam unhindered. It strikes the scattered light body (13) and

produces scattered light that is picked up by detector (8). The shutter (12)

is closed and blocks the scattered light coming from the flow cell.

3. Zero point check value: The attenuator (11) reduces the checking beam

intensity to 1%. The scattered light produced by the scattered light body is

picked up by the scattered light detector (8). The shutter (12) is closed

and blocks the scattered light coming from the flow cell.

The periodically detected values are compared with the nominal values. In

the event of an excessive deviation, a warning is given.

All these features described above from the highly stable laser light

source to the various self control mechanisms allow an extension of the

maintenance interval to 3 months, which gives significant relief to the

operators.

3 Extractive sampling system

For flue gases which are normally or occasionally saturated with water or

acid gases, e.g. after wet scrubbers or flue gas desulfurication units,

interference with optical measurement may occur due to fluid droplets also

scattering the light. To overcome this problem, the sample for the scattered

light measurement in the StackGuard is extracted from the stack and heated

in a sampling line up to 160°C. Some national regulations like PS 11 in the

U.S. even require extractive arrangements for this type of applications.

Figure 3 shows the complete setup of the StackGuard including the loop line

for sample preparation.

Figure 3: StackGuard measuring system including ring pipe

|

The sampling line (c) takes the sample from the

stack (d) at a flow rate of 60 m3/h using a blower (e). This

high flow rate is chosen for two reasons. One, to ensure representative

sampling, and second, to prevent deposits by using a high gas velocity

in the loop line. From this loop line, the sample for the photometer (b)

is taken with a flow rate of 35 l/min. The probe of the CTNR sampling

line in the stack uses over-isokinetic sampling with a factor of 1.5 to

reduce the relative error for changing gas flow velocities in the stack.

The absolute error is considered with the calibration of the instrument.

Using temperature controlled heaters, the sample temperature is kept at

a level of at least 160°C. The control unit (a) handles the operation,

control, display, and signal processing functions.

The photometer is built up in two completely

separated compartments. The first compartment contains all the

electronics, light source, detector, chopper, and the related optical

elements. The sample compartment contains the flow cell for the

detection of the particles by scattered light measurement (Figure 4).

The sample enters the flow cell from top (P1). A heated and filtered

purge air flow (S1) surrounds the sample stream with a protective

shroud, and additional purge air injection in front of the optical

lenses S2 prevents soiling of the optical surfaces L1 and L2. Sample and

purge air leave the cell at the bottom outlet (P2).

This setup makes the cell insensitive to any

changes of the signal caused by soiling even for gas streams with high

particle load. As given above, the drift of the complete instrument

including errors by potential deposits on the windows, is less than 2%

per 3 months and can be easily adjusted using optical control glasses. |

Figure 4: Sample flow cell of StackGuard

Figure 4: Sample flow cell of StackGuard |

4 Calibration

All instruments are factory calibrated related to PLA (polystyrene latex

aerosol) spherical particles with a diameter of 1 micrometer to ensure the

linearity of the calibration over the complete measuring span. The on-site

calibration relating to the actual particle load usually can be done just by

inserting a fix factor between the PLA value and the real value in mg/m3.

Usually, this factor can vary between 1.0 and 40.0, depending on the

characteristics of the particles as size distribution, material, surface

structure, refractive index, etc.

For the calibration of the particulate matter CEMS in these low ranges,

exceeding accuracy has to be taken for the reference method. It is obvious,

that the accuracy of the calibration (and thus the accuracy of the

continuous measurement done later on) cannot be better than the accuracy of

the manual method. So either a well-known method like given e.g. in the

guideline VDI 2066 should be used, or paired data with two trains should be

collected for the manual method. The latter is especially the case, if a

well-known method is modified, or if the results are not satisfying. The

paired data approach will allow evaluating in a first step the accuracy of

the manual method before starting the calculation of the calibration curve.

To test the manual method, a plot of train 1 versus train 2 should be done,

where the slope should be near to 1 and the correlation coefficient should

be 0.95 or better. Otherwise the manual method has to be improved. The

method applied for the results given below is the manual method according to

guideline DIN EN 13284, part 1, April 2002.

5 Field test

To demonstrate the increased sensitivity and stability of the StackGuard

instrument compared to its predecessors, a test installation at a municipal

incinerator waste incinerator has been done. The unit was installed

specifically in the intermediate gas duct following the scrubber and ahead

of the flue gas nitrogen oxide control. It has been investigated within the

suitability test of the system (TÜV-Bericht 936/21202165/A, 2005).

The measuring systems were installed in a horizontal flue gas duct. The

inlet and outlet sections were at least three times the diameter. The duct’s

circular cross-section is 1.60 m in diameter. The intake openings of the

measuring installations were arranged at the measuring level, spaced less

than 0.3 m apart. The measuring level for the reference measurements was

located in the measurement volume of the measuring installations.

The particle emission of this facility is under normal operating

conditions around 1 mg/dsm3. Values between 0.4 mg/dsm3

and 2.4 mg/dsm3 have been seen during the campaign of 6 months.

An artificial spreading of the values by modification of the operating

conditions is no longer allowed according to EN 14181 standard. Two

instruments have been installed for 6 months and within this time two

measuring campaigns of 17, resp. 16 test runs using manual reference method

have been carried out. The measuring range used for this test was 0..1 mg/m3 PLA.

The results are given in table 1 and figures 5 and 6, respectively.

| Test run no. |

Particle concentration reference method [mg/dsm3] |

StackGuard Instrument 20 [mA] |

StackGuard Instrument 21 [mA] |

| 1 |

2.0 |

6.26 |

6.48 |

| 2 |

2.0 |

6.30 |

6.39 |

| 3 |

1.6 |

6.29 |

6.43 |

| 4 |

2.3 |

6.27 |

6.43 |

| 5 |

1.9 |

5.79 |

5.89 |

| 6 |

1.9 |

5.80 |

5.93 |

| 7 |

1.5 |

5.84 |

5.91 |

| 8 |

0.6 |

4.45 |

4.46 |

| 9 |

0.6 |

4.46 |

4.46 |

| 10 |

0.6 |

4.44 |

4.44 |

| 11 |

0.7 |

4.46 |

4.46 |

| 12 |

0.7 |

4.49 |

4.49 |

| 13 |

0.7 |

4.44 |

4.44 |

| 14 |

0.7 |

4.45 |

4.46 |

| 15 |

0.7 |

4.42 |

4.44 |

| 16 |

0.4 |

4.42 |

4.43 |

Table 1: Results of StackGuard on waste incinerator

| Regression analysis results: correlation coefficient: 0.93 |

| ------- |

confidence interval |

| ____ |

tolerance interval |

|

| Figure 5: Calibration of StackGuard No. 20 on waste incinerator |

| Regression analysis results: correlation coefficient: 0.93 |

| ------- |

confidence interval |

| ____ |

tolerance interval |

|

| Figure 6: Calibration of StackGuard No. 21 on waste incinerator |

Although the low values of the manual reference method have been at the

limit of this method, the statistical values demonstrate a good reliability.

Also both investigated instruments react very homogeneous. Full scale in the

selected measuring range of 1 mg/m3 PLA is corresponding to a

particulate matter concentration of approximately 12.5 mg/m3. The

lowest detected concentration was 0.4 mg/dsm3. The lowest

detectable concentration, which is mainly determined by the stray light

background, was determined to 1% of full scale in the lowest possible range

of 0 to 0.05 mg/m3 PLA, i.e. 0.006 mg/dsm3.

The tests reported in this paper have been successfully performed by TÜV

Rheinland in Germany, leading finally to approval of the StackGuard for use

with power stations and waste incinerators according to 13th and

17th BImSchV and TA Luft.

6 References

Huber, E. and M. Frost (1998), "Light scattering by small particles",

aqua, Vol.47

TÜV-Bericht 936/21202165/A (2005), Bericht über die Eignungsprüfung der

Messeinrichtung StackGuard der Firma Sigrist-Photometer in

Ennetbürgen/Schweiz

TÜV-Bericht 936/806015 (1997), Bericht über die Eignungsprüfung des

Staubmessgerätes CTNR der Firma Sigrist-Photometer, Ennetbürgen (CH)

Products: StackGuard

Figure 4: Sample flow cell of StackGuard

Figure 4: Sample flow cell of StackGuard