1946 – The Innovation for Breweries

The history of Sigrist-Photometer AG began in 1946, when the company’s founder Dr. Ing. Willy Sigrist (21 March 1907 – 1 August 1988) developed a turbidity measuring device in Ennetbürgen for the continuous monitoring of beer filtration.

Even back then, turbidity in beer was considered a key quality indicator. However, it could not be measured during the brewing process itself. Photometric measurements at that time were only available for individual samples in the laboratory. The only possible quality control during the process was therefore visual inspection by the trained eye of the brewer.

First Online Turbidity Measuring Device

This changed abruptly when the founder of today’s Filtrox AG in St. Gallen approached Dr. Sigrist with a request. He asked him to develop an online measuring device to precisely determine the effectiveness of his high-quality filters in beer filtration. Not only were the two connected through their shared time studying at the Polytechnic University in Zurich — they also shared a commitment to high-quality, reliable, and precise products.

Dr. Sigrist subsequently developed such a device to the full satisfaction of Filtrox, laying the foundation for the innovative flicker mirror technology and at the same time for an over 80-year success story — that of Sigrist-Photometer AG.

Principle of Flicker Mirror Technology

At that time, manufacturing a precise and long-term stable measuring device was a major challenge. Neither the light sources nor the optical detectors or amplifiers were stable over long periods.

The idea was to use a flicker mirror to split the light beam into two beams. One beam was directed through the measuring cell to the photocell, while the other served as a reference beam. With the help of an optical aperture, the intensity could be adjusted and the measured value determined.

Even then, Sigrist placed great emphasis on top quality. The flicker mirrors were tested for three months before installation. In addition to tube electronics, the mechanical component share was enormous — up to 10,000 individual parts per device.

K Devices and C Series

With the introduction of transistors in the 1980s, the K devices (K for KOMPAKT / compact) were developed.

At the end of the 1990s, these were replaced by the new C series. A measuring and reference channel was added. Absolute light levels were measured for the first time. This technology increased device sensitivity by a factor of 10. The dynamic range was massively expanded so that optical measuring range switching was no longer necessary. The C devices could be recognized by their shortened base units and stainless steel housings.

Sigrist photometers were no longer used only in breweries. With the development of a new generation of devices, application-specific instruments were added to the portfolio. The first product of this device family was the WTM 500, a turbidity meter for measuring drinking water in free fall. For the brewing sector, the DualScat was developed, which remained Sigrist’s most important device until 2009 and is still in use by some Sigrist customers today.

The innovation was that the device could be connected directly to a standard housing — meaning it could be easily and compactly integrated into a product line. This enabled simple and hygienic installation as well as optimal cleanability, for example in the beer filtration process.

The DualScat used multiple detectors for the first time, enabling simultaneous measurement of transmitted light, 90° scattered light, and 25° forward scattered light. Using transmitted light measurement, color-related absorption in the medium, window contamination, and fluctuations in the light source could be compensated. To ensure long-term stability, each DualScat featured a solid reference control unit that allowed easy verification of device stability. And the devices proved to be extremely stable: one DualScat still in operation at Sigrist has accumulated 170,000 operating hours, and its measured values require less than 2% correction for proper calibration.

The optical setup was very compact, the electronics met the latest requirements, and mechanical adaptation to the process line was very simple. The device volume was reduced by a factor of 10 compared to the predecessor model.

In parallel with the DualScat, a new laboratory device — the LabScat — was developed in 1999. Compared to its predecessor model KTL 30, it represented a major leap in optics and technology and remains part of the Sigrist brewing portfolio today as the 2nd generation LabScat, thanks to continuous development and optimization. The two-angle laboratory turbidity meter is the ideal complement to process instruments for final quality assurance in the lab.

The device has a very compact design and can be cleaned quickly without tools. A valve unit also enables complete draining of the water bath. These features provide the following benefits:

- Minimal space requirements on the laboratory bench

- Measurement capability for all common bottle types

The convincing measurement technology is reflected in the combination of high-quality optical components with proven dual-beam technology. It enables extremely low baseline brightness. The bottle or cuvette is centered at the start of measurement and rotated in the water bath during measurement. This achieves:

- Stable measurement from a few mEBC up to 500 EBC (e.g., for dark wheat beers), even at 0 °C

- Reduction of bottle-related interference, ensuring more precise measurement

- Compensation of window deposits and color influences from bottle and medium

TurBiScat – A Star Is Born

Since 1946, the name Sigrist-Photometer AG has been firmly associated with turbidity measurement in beer filtration. Our commitment to the highest quality and precision, durability, and reliability has now been upheld for 80 years. This is reflected in the continuous optimization of existing products and development of new ones. In 2009, another innovation was added to the Sigrist portfolio — the TurBiScat. With its combination of precise two-angle scattered light measurement, color measurement option, and near maintenance-free operation, our in-line process turbidity meter is ideally suited to today’s requirements of our international customers.

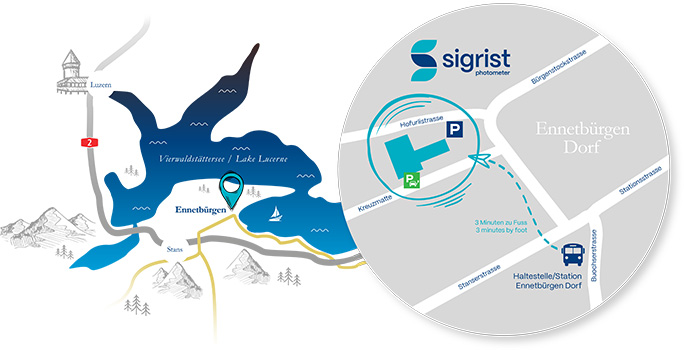

The secret of the high quality standard lies in its “Swissness.” The devices are developed and manufactured at our headquarters in Ennetbürgen and individually tested before shipment according to strict ISO 9000:2008 quality standards.

The sophisticated device design together with the use of high-quality optical components enables unmatched measurement precision. The TurBiScat achieves a resolution of 0.001 EBC with repeatability of ±0.001 EBC. Reproducibility between two devices is ±0.02 EBC with a fast response time of less than two seconds (step response).

The TurBiScat determines turbidity with optimal color compensation using 650 nm scattered light measurement and is therefore MEBAK/EBC compliant. Adapted to individual needs and applications, the device covers a measuring range from 0 – 1000 EBC and can be configured for single- or dual-angle measurement. The dual-angle method significantly increases the informative value of turbidity measurement. In addition to standard filtration monitoring at 90°, the additional 25° measuring angle enables:

- Monitoring of filter structure

- Early warning of filter breakthrough

Optionally, the TurBiScat can be equipped with an integrated MEBAK/EBC/ASBC-compliant color measurement (430 nm) up to 50 EBC / SRM 25.4. This flexible 3-in-1 integration provides cost advantages in procurement and savings in process connections. Another benefit is the wide range of applications — from the brewhouse to the filtration cellar and up to the pressure tank.

At the same time, the portfolio was expanded with additional application-specific devices for monitoring the brewing process. PhaseGuard, TurbiGuard, and ColorPlus were further developed and — like the TurBiScat — are now successfully used in breweries in their second device generation.

We will show how these devices optimally support the brewmaster during brewing in future articles.

Information on the individual devices and applications can be found on our website: www.sigrist.com.