Water is one of the four main ingredients in beer brewing, along with malt, hops and yeast. And it makes up a large proportion: Beer consists of around 90% water. Although it is often taken for granted, water plays a decisive role in the flavour, quality and consistency of beer.

The composition of the water with minerals and salts, hardness and residual alkalinity influences the brewing process itself and then the flavour of the beer. For example, hard water, which is rich in calcium and magnesium, can emphasise the flavour of hops, while soft water is more suitable for milder beers. Historically, the water sources of a region have often characterised the beer style. Malt in particular was then selected to match the available water. Famous beer styles such as Munich dark beer, Pilsner from Pilsen or Burton Ale from Burton-on-Trent owe their unique flavour to the specific water composition of these places.

Today, the water in the brewery can be treated in such a way that beers of different styles can be brewed in one brewery.

The water can have different origins:

- Groundwater from a private well, often several hundred metres deep

- Surface water from rivers or reservoirs

- Water sources

- from the public water supply

Regardless of the source of the water, the brewer must ensure that the quality is right even before the actual brewing process begins.

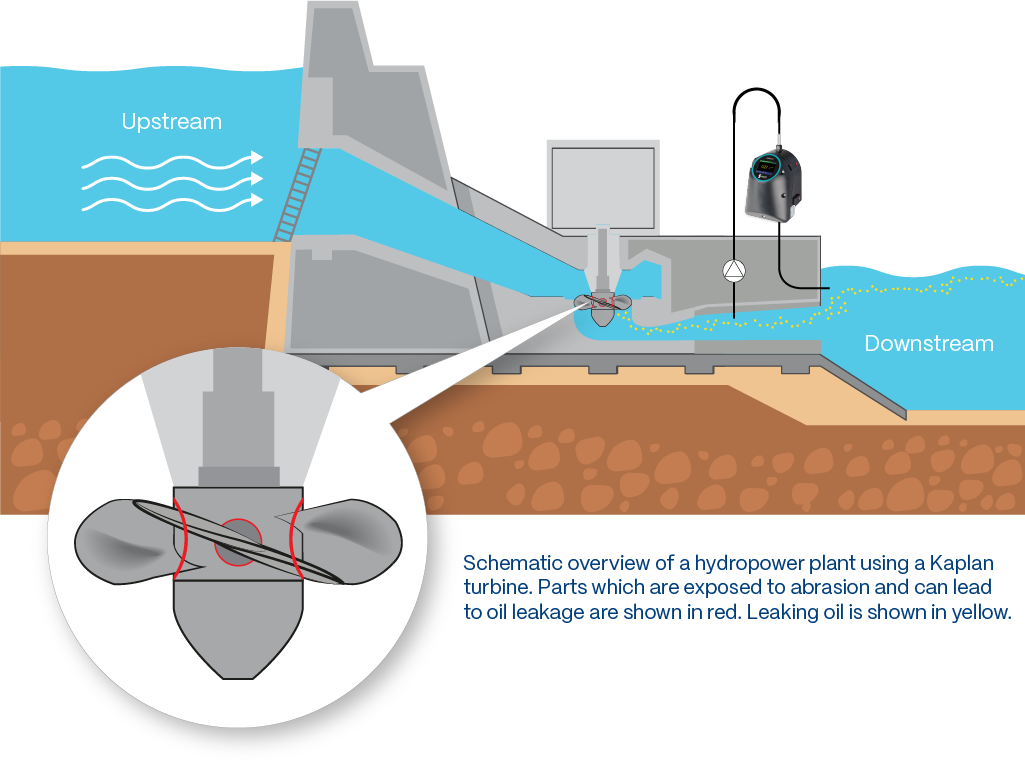

Turbidity is a particularly important parameter for surface and spring water.

Turbidity can be measured easily, accurately and reliably using various turbidity measuring photometers from the AquaScat-series or the AquaScat S probe.

The AquaDMS measures potential disinfectant residues in tap water.

AquaGuard PR 30 and AquaMaster measure turbidity as well as other parameters such as pH value, nitrate, etc.

An accident could potentially occur in the catchment area of springs or in surface water where oil gets into the water. Even the smallest amounts of oil can render the water unusable. Our OilGuard 2 W and OilGuard PR 30 ensure that contaminated water can be detected and discarded in good time.

Regardless of the combination of these devices, we are happy to help you ensure that your water not only fulfils the local requirements for drinking water, but is truly excellent brewing water. And we can then toast with a good beer at the end.